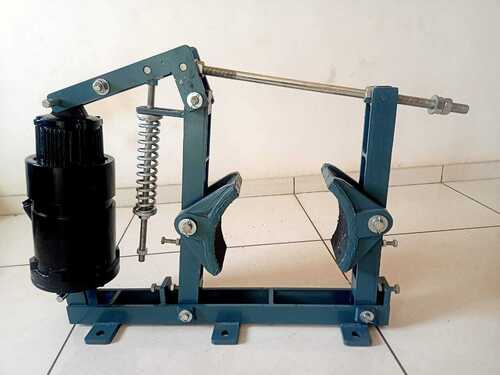

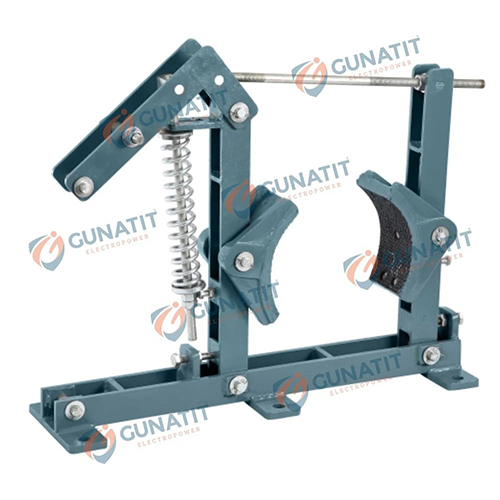

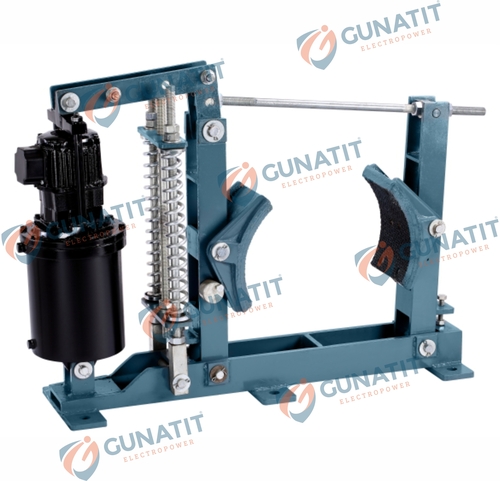

Electro Hydraulic Thruster Brake

Price 7200 INR/ Set

MOQ : 10 Sets

Electro Hydraulic Thruster Brake Specification

- Condition

- New

- Usage

- Industrial

- Size

- 100-400mm

- Product Type

- Electro hydrulic thruster brake

- Weight

- 30 Kilograms (kg)

- Color

- Black

- Power Supply

- Electric

- Voltage

- 220 Volt (v)

Electro Hydraulic Thruster Brake Trade Information

- Minimum Order Quantity

- 10 Sets

- FOB Port

- MUNDRA PORT

- Payment Terms

- Cash on Delivery (COD), Cheque

- Supply Ability

- 50 Sets Per Week

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- WOODEN CASE PACKING IS REQUIRED

- Main Domestic Market

- All India

- Certifications

- AN ISO 9001 : 2008 CERTIFIED COMPANY

About Electro Hydraulic Thruster Brake

An electro-hydraulic thruster brake, also known as an electro-hydraulic brake, is a type of braking system used in various industrial applications to provide stopping or holding of heavy machinery and equipment. It combines both electrical and hydraulic elements to control the braking force.Heres how it works: 1. Electrical Control: The system is initiated by an electrical signal or command, which can be manual or automatic, depending on the application and requirements. This electrical control can be in the form of a switch, button, PLC (Programmable Logic Controller), or other control systems.2. Electromagnetic Thruster: An electromagnetic thruster is the key component of the electro-hydraulic thruster brake. When the electrical command is given, it energizes the electromagnetic coil, which produces a magnetic field.3. Hydraulic Actuation: The magnetic field generated by the electromagnetic coil acts on a plunger, which is connected to a hydraulic system. The plunger moves when the electromagnetic coil is energized, causing hydraulic fluid to be pressurized.4. Brake Shoes and Drum: The pressurized hydraulic fluid is used to actuate brake shoes that press against a brake drum. The brake drum is usually mounted on the rotating shaft of the machinery or equipment that needs to be stopped or held.5. Friction and Braking: As the brake shoes make contact with the brake drum, friction is created, which generates the braking force. The amount of pressure applied to the brake shoes can be controlled, allowing for precise and variable braking force as needed for the application.6. Release: When the electrical signal is cut off or released, the electromagnetic coil de-energizes, and the hydraulic pressure on the brake shoes is released, allowing the machinery to move freely.FAQ: 1. What is a hydraulic electro-thruster brake?Ans: A hydraulic electro-thruster brake is a braking system commonly used in industrial applications to provide controlled stopping and holding of heavy machinery. It combines electrical and hydraulic components to generate braking force.2. How does an electro-thruster brake work?Ans: When an electrical command is given, an electromagnetic thruster coil generates a magnetic field, which activates a hydraulic plunger. This pressurizes hydraulic fluid, causing brake shoes to make contact with a brake drum, creating friction and generating the braking force.3. Where are hydraulic electro-thruster brakes commonly used?Ans: They are used in various industrial settings, including cranes, hoists, winches, conveyors, and other heavy machinery that require controlled stopping and holding capabilities.4. What are the advantages of hydraulic electro-thruster brakes?Ans: Some advantages include precise control over braking force, quick response times, and the ability to securely hold heavy loads. They are essential for safety and operational efficiency in many industrial applications.5. Can the braking force be adjusted or controlledAns: Yes, the amount of pressure applied to the brake shoes can be controlled, allowing for variable braking force. This adjustability is important in applications where different loads or stopping requirements are encountered.6. Are electro-thruster brakes reliable?Ans: When properly maintained and operated, electro-thruster brakes are known for their reliability. Regular inspections, maintenance, and adherence to safety standards are important to ensure their continued reliability.7. What happens when the electrical signal is cut off or released?Ans: When the electrical signal is released, the electromagnetic coil de-energizes, and the hydraulic pressure on the brake shoes is released, allowing the machinery to move freely.8. Are these brakes suitable for emergency stopping situations?Ans: Electro-thruster brakes are designed to provide controlled and reliable stopping but may not be ideal for emergency stops. In emergency situations, additional safety mechanisms or backup braking systems are often used.9. How can I maintain and troubleshoot electro-thruster brakes?Ans: Regular maintenance, including checking hydraulic fluid levels, inspecting brake shoes and drums, and verifying electrical connections, is important. If issues arise, consult the manufacturers documentation or a qualified technician for troubleshooting and repair.10. Are there alternatives to electro-thruster brakes for braking applications?Ans: Yes, other braking systems like electromagnetic brakes, mechanical brakes, and pneumatic brakes are also used in various applications. The choice depends on the specific requirements of the machinery and the application.Download PDF of Electro Hydraulic Thruster Brake:FAQs of Electro Hydraulic Thruster Brake:

Q: What type of brake is the Electro Hydraulic Thruster Brake?

A: The Electro Hydraulic Thruster Brake is a brake drum type.Q: What is the voltage requirement for this brake?

A: The brake operates at a voltage of 220 Volt (v).Q: What material is used to manufacture the Electro Hydraulic Thruster Brake?

A: The brake is made of MS (Mild Steel).Q: What are the size specifications of the Electro Hydraulic Thruster Brake?

A: The brake size ranges from 100mm to 400mm.Q: Does the product come with a warranty? If yes, for how long?

A: Yes, the product comes with a 1-year warranty.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thruster Brake Category

Thruster Operated Brake

Price 10200.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Condition : New

Color : Grey

Standard : ISO

Material : MS

Thruster Brake 18 Kg

Price 6000 INR / Number

Minimum Order Quantity : 1 Piece

Condition : New

Color : Black

Standard : ISO

Material : C.I

EOT Crane Brake Shoe

Price 1500 INR / Set

Minimum Order Quantity : 1 Set

Condition : New

Color : White

Standard : ISO

Material : C.I

Electro Hydraulic Thrusters

Price 7000 INR / Number

Minimum Order Quantity : 10

Condition : New

Color : Black

Standard : ISO

Material : MS

08045801632

08045801632

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS