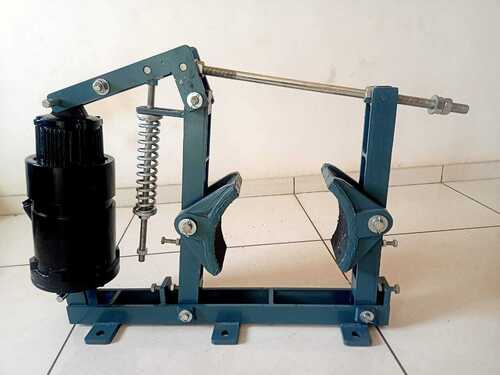

EOT Crane Brake Shoes

Price 1500.0 INR/ Piece

MOQ : 2 Sets

EOT Crane Brake Shoes Specification

- Condition

- New

- Usage

- Industrial

- Load Capacity

- 500 Kilograms (kg)

- Product Type

- THRUSTER BRAKE SHOE

- Weight

- 10 Kilograms (kg)

- Color

- Gray

- Operating Mode

- Automatic

- Power Supply

- Electric

EOT Crane Brake Shoes Trade Information

- Minimum Order Quantity

- 2 Sets

- FOB Port

- mundra , india

- Supply Ability

- 50 Sets Per Week

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- CARTOON BOX PACKING

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- AN ISO 9001 : 2008 CERTIFIED COMPANY

About EOT Crane Brake Shoes

Overhead crane brake shoes are an essential component of the braking system in overhead cranes. These shoes play a crucial role in stopping and holding the load, ensuring the safety and proper functioning of the crane.

Here are some key points about overhead crane brake shoes:

1. Functionality:

Brake shoes are part of the braking system that slows down and stops the motion of the crane.

They create friction against the brake drum or disc to generate the necessary stopping force.

2. Material:

Brake shoes are typically made of high-friction materials that can withstand the heat generated during braking.

Common materials include various formulations of friction materials such as organic, semi-metallic, or ceramic.

3. Wear and Tear:

Over time, brake shoes can wear down due to the constant friction against the braking surface.

Regular inspection and maintenance are crucial to ensure that the brake shoes are in good condition and provide effective braking.

4. Adjustment:

Brake shoes may need periodic adjustment to maintain proper clearance and ensure optimal braking performance.

Improperly adjusted brakes can lead to reduced braking efficiency and safety concerns.

5. Replacement:

When brake shoes reach the end of their service life or show signs of significant wear, they need to be replaced.

Replacement intervals depend on factors such as usage, load capacity, and operating conditions.

6. Safety Considerations:

The proper functioning of overhead crane brake shoes is critical for the safety of both personnel and equipment.

Regular inspections, adherence to maintenance schedules, and prompt replacement of worn-out components contribute to a safe working environment.

7. Installation and Maintenance:

Installation and maintenance procedures should follow the manufacturers recommendations and guidelines.

Maintenance tasks may include lubrication, adjustment, and visual inspection of the brake shoes.

Crane Brake Shoe Specifications:

1. Loading Capacity: 500 Kg

2. Position: Center

3. Type: Brake Shoes, Brake lining

4. Model Name/Number: BS MDT 100-600MM

5. Surface Finishing: Yes

6. Automation Grade: Manual

7. Diameter: 100mm To 600mm

8. Features: Non Ductile Heavy Cast With Asbestos Liner

9. Material: Cast Iron

Frequently Asked Questions (FAQs):

1. What is the purpose of overhead crane brake shoes?

Ans: Overhead crane brake shoes are a crucial component of the braking system, responsible for slowing down and stopping the motion of the crane. They create friction against a braking surface (drum or disc) to generate the necessary stopping force.

2. How do I know when the brake shoes on my overhead crane need replacement?

Ans: Signs of wear, reduced braking efficiency, unusual noises during braking, or visible damage are indicators that brake shoes may need replacement. Regular inspections and adherence to maintenance schedules are essential for early detection.

3. What types of materials are used for overhead crane brake shoes?

Ans: Brake shoes are typically made of high-friction materials to withstand the heat generated during braking. Common materials include organic compounds, semi-metallic formulations, and ceramic materials.

4. How often should I inspect and maintain overhead crane brake shoes?

Ans: Regular inspections should be conducted according to the manufacturers recommendations. The frequency of inspections depends on factors such as usage, load capacity, and operating conditions. Routine maintenance tasks may include lubrication, adjustment, and visual inspection.

5. Can I adjust the brake shoes on my overhead crane?

Ans: Yes, brake shoes may require periodic adjustment to maintain proper clearance and ensure optimal braking performance. Improperly adjusted brakes can lead to reduced efficiency and safety concerns.

6. Are there different types of brakes used in overhead cranes?

Ans: Yes, overhead cranes can have different types of brakes, such as drum brakes or disc brakes. The design and type of brake used depend on the crane model and manufacturer.

7. What safety considerations should I keep in mind regarding overhead crane brake shoes?

Ans: The proper functioning of brake shoes is critical for the safety of personnel and equipment. Regular inspections, adherence to maintenance schedules, and prompt replacement of worn-out components contribute to a safe working environment.

8. Can I replace the brake shoes on my overhead crane myself?

Ans: Replacement of brake shoes should be done by trained personnel following the manufacturers guidelines and recommendations. Its essential to follow proper installation and maintenance procedures to ensure the continued safety and efficiency of the braking system.

9. What is the typical service life of overhead crane brake shoes?

Ans: The service life of brake shoes varies based on factors such as usage, load capacity, and operating conditions. Regular inspections and monitoring of wear patterns can help determine when replacement is necessary.

10. Are there specific regulations or standards for overhead crane brake systems?

Ans: Yes, various safety standards and regulations govern the design, installation, and maintenance of overhead cranes, including their brake systems. Its crucial to comply with these standards to ensure the safe operation of the equipment.

ISO Certified Quality and Durability

Our EOT Crane Brake Shoes are meticulously produced to comply with ISO standards, ensuring long-lasting quality and consistent performance. Constructed from premium mild steel, these brake shoes are robust enough to withstand continuous industrial usage, making them a dependable choice for crane operations across various sectors.

Hassle-Free Installation and Operation

Designed for automatic operation with an electric power supply, installation of the brake shoes is straightforward and efficient. The gray-finished shoes fit seamlessly with standard brake drums, delivering optimal braking power and smoothed stopping action for EOT cranes, supporting your workflow with minimal downtime.

FAQs of EOT Crane Brake Shoes:

Q: How are EOT Crane Brake Shoes installed and operated?

A: The EOT Crane Brake Shoes are designed for easy installation on standard crane brake drums. Once fitted, their automatic operation is activated via an electric power supply, ensuring reliable and efficient braking performance during crane usage.Q: What is the warranty and lifespan of these brake shoes?

A: Each set of brake shoes comes with a 1-year warranty, reflecting confidence in durability and material quality. With proper use in industrial settings, they offer a long service life due to their sturdy MS construction and adherence to ISO standards.Q: When should I replace EOT Crane Brake Shoes?

A: Replacement is recommended when you observe reduced braking efficiency or visible wear on the shoes. Regular inspections help maintain optimal performance, and timely replacement avoids safety risks during crane operations.Q: Where can I use these brake shoes effectively?

A: These brake shoes are engineered for industrial environments where EOT cranes are employed, suitable for applications with a load capacity up to 500 kg. Their compatibility makes them ideal for warehouses, manufacturing plants, and heavy-duty workshops across India.Q: What is the process of ordering or sourcing these brake shoes?

A: As a distributor, exporter, manufacturer, supplier, and trader in India, we facilitate streamlined ordering through direct contact channels. Reach out to discuss your requirements, and well provide fitting guidance and prompt delivery.Q: How do these brake shoes benefit crane operations?

A: The brake shoes enhance overall safety and operational precision by ensuring dependable stopping power for crane drums. Their robust construction and electric automatic operation reduce maintenance needs and improve workflow efficiency.Q: What makes these brake shoes suitable for industrial usage?

A: Crafted from high-grade mild steel and built to ISO standards, these brake shoes are designed to endure high-frequency industrial tasks. Their load handling capacity and new condition ensure they meet the rigorous demands of continuous operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thruster Brake Category

Electro Hydraulic Thruster Brake

Price 7200 INR / Set

Minimum Order Quantity : 10 Sets

Condition : New

Power Supply : Electric

Color : Black

Usage : Industrial

EOT Crane Brake Shoe

Price 1500 INR / Set

Minimum Order Quantity : 1 Set

Condition : New

Power Supply : Manual

Color : White

Usage : Industrial

EOT Crane Brake System

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Supply : Electric

Usage : Industrial

Electro Hydraulic Thrusters

Price 7000 INR / Number

Minimum Order Quantity : 10

Condition : New

Power Supply : Electric

Color : Black

Usage : Industrial

08045801632

08045801632

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free